|

MILD STEEL TUBE MILLS |

|

|

|

|

|

|

|

|

|

Cut Off Machine |

|

Forming Machine Rear Stage |

|

|

|

|

| Mild Steel Tube Mills is used mainly for producing different sizes of carbon steel round pipe, square pipe, and rectangular pipe. |

|

|

| Industry, construction, furniture, medical use, etc. |

|

|

| Model |

Production Range

m/m O.D |

Shaft

m/m |

Motor

HP |

H/F Welding m/c

Out Put kw |

Production

Speed |

Tolerance

m/m |

| YTM1 |

114.3-216.3 |

100 |

DC120*2

VS200 |

350KW |

6-30M/min |

± 0.05 |

| YTM2 |

76.2-114.3 |

80 |

DC80*2

VS150 |

250KW |

20-60M/min |

± 0.05 |

| YTM3 |

50.8-76.2 |

60 |

DC75*2

VS120 |

200KW |

25-60M/min |

± 0.05 |

| YTM4 |

38.1-50.8 |

50 |

DC40*2

VS75 |

150KW |

35-80M/min |

± 0.05 |

| YTM5 |

25.4-31.8 |

40 |

DC25*2

VS20 |

100KW |

50-100M/min |

± 0.05 |

| YTM6 |

9.5-22.2 |

35 |

DC20*2

VS30 |

75KW |

60-120M/min |

± 0.05 |

| YTM7 |

6.0-14 |

30 |

DC15*2

VS25 |

75KW |

60-120M/min |

± 0.05 |

|

|

|

a. Our machines are manufactured from finest materials. Steady, durable and long life.

b. Automatic control, easy to operate.

c. Easy to replace the molds, save working hour and increase efficiency.

d. Low noise. |

|

|

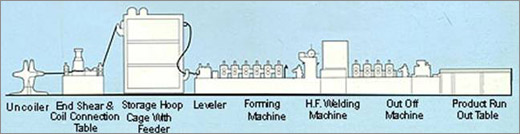

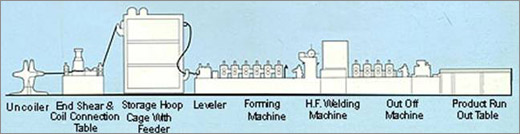

First, the coil is set onto the uncoiler, and the steel belt is loosened and rolled into the storage cage, before being transported into the forming machine.

The steel belt is first flattened out, and is processed through rollers to squeeze it to the desired pipe diameter.

The machine then welds, straightens and cuts the pipe to the length set in the automated cut-off machine, and transports the finished pipe to the run out table, where quality inspection can be performed

. |

|

|

1. Coil→2. Flattening→3. Forming→4. Welding→5. Cooling→6. Outside bead remove→7. Sizing→8. Cutting→9. Product Run Out Table→10. Inspection→11. Packing→12.Finished pipe

Rollers Rollers |

|

|

MILD STEEL TUBE MILLS RELATED PRODUCTS |

|

|

|

Rollers

Rollers